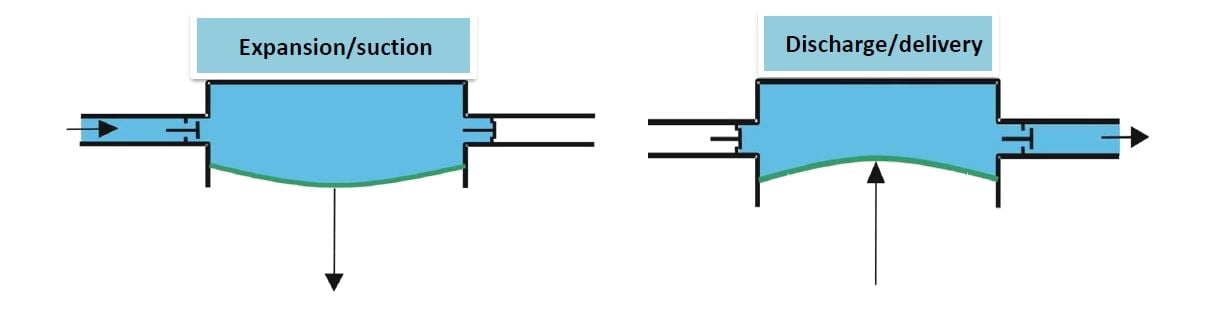

A backward movement of the piston allows liquid to enter into the cylinder and forward movement causes discharge as shown in the above figure. They have less cost.

Advantages Of Diaphragm Pumps Yamada Pump

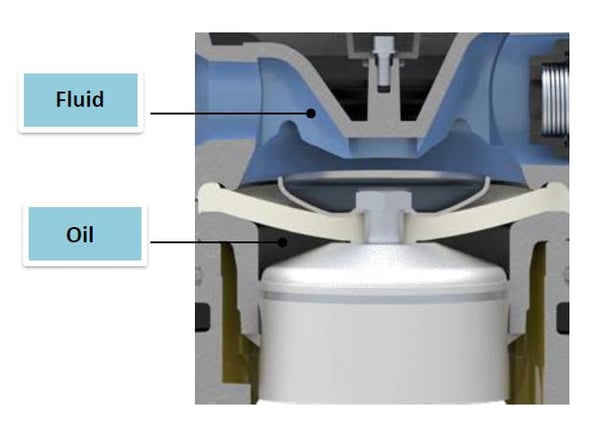

The elastic component is usually in the form of a diaphragm.

. There are very less frictional losses. A pump is a mechanical device used to move fluids solids or slurries from one place to another by mechanical action. The complex electronics at both ends of the line tends to be more expensive.

Immune to corrosion Disadvantages of Fibre Optic. These pumps have small sizes. However due to the variety of factors described in this article that may impact on rotary lobe pump performance developing a specific pump performance curve for a particular application is key to choosing the correct size of pump for the job.

Immune to electrical interference. Low recovery and relatively low coefficient of flow Cv. The Bourdon pressure gauge uses the principle that a flattened tube tends to change to a more circular cross-section when pressurized.

Folded plate structures very light form of construction up to span 30 m shell thickness required is 60 mm only. Positive displacement 3-chamber diaphragm pump This solar-powered submersible well pump from Pentair takes the cake for reliability. High pressure drop higher pump capacity and system wear More expensive than other valves The sealing device is a plug that offers limited shut-off capabilities not.

The major disadvantages of Reciprocating Pumps are. These are some disadvantages of Pump. Maintenance is very high due to the wear and tear.

A diaphragm pump is the most efficient. On the other hand diaphragm shapes can be circular flat or corrugated. In this article we will discuss various types of pumps and their applicationsWe suggest you also read this article on the types of actuators used to control.

The construction of the pump is Simple. They can control low to medium viscosity fluids. They are best for low head to medium head.

Piston plunger and diaphragm cause reciprocating action which sucks the liquid from the suction and a fixed amount of liquid is discharged by pushing them into the cylinder. Contact us at 417 831-1411 to discuss your specific rotary lobe pump. To accomplish this they typically shut down the flow of outside air to a mixing box when the.

It has a longer span that can be provided. Needs specialist expertise to lay fibre and many installers are more familiar with copper cable. As there is no drive seal so there is no leakage in the pump.

Diaphragm elements are advantageous in highly corrosive environments or with over-pressure systems. The pump is encased in an extremely durable stainless steel and Santoprene diaphragm and features valves made of EDPM synthetic rubber. The movement of the diaphragm regulates the pressure.

Also has flat shapes by choosing certain arched shapes. Reciprocating Pump Advantages Disadvantage. The purpose of an air coil freeze stat is to keep the refrigerant-to-air heat exchanger commonly called air coils from freezingThis kind of freeze stat is typically used for heating coils which are exposed to outside air and is usually installed on the supply air side of the coil.

Although this change in cross-section may be hardly noticeable the displacement of the material of the tube is magnified by forming the tube into a C shape or even a helix such that the entire tube tends to straighten out or uncoil elastically as it. The main advantages are the speed and the completeness of transfer compared to diffusion or vacuum blotting. Advantages and Disadvantages of Dynamic Pumps Advantages Dynamic Pump.

Advantages of Fibre Optic. This pump uses more than one cylinder for pressurizing the water. Ionization from gamma rays can cause three different reactions in living cell tissues.

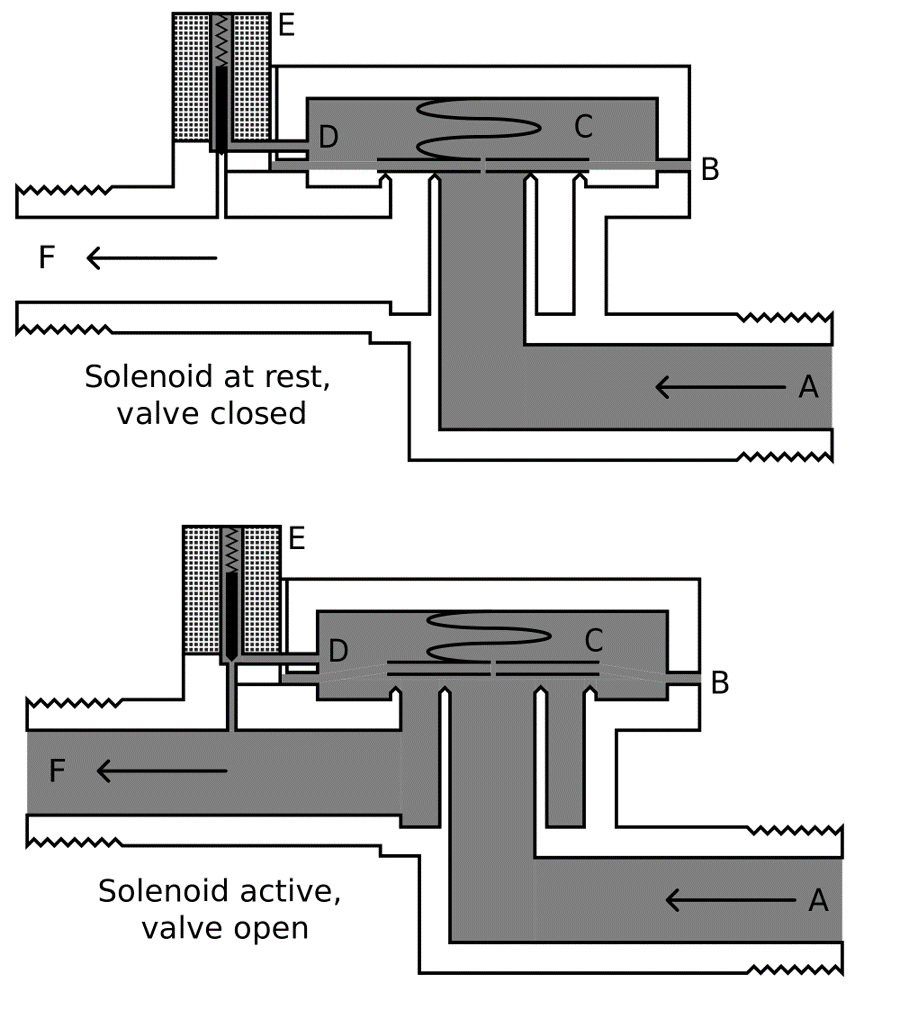

Advantages of folded plate structures. The compressed air which flows through a controlled cross-section at the valve seat acts on the other side of the diaphragm. Various types of pumps are available in the market according to their working principle and applications.

It is less efficient than a multistage pump. These are some advantages of Pump. In a single-acting piston pump pump sucked liquid in suction stroke and the pump delivers liquid in discharge.

The diaphragm has a large surface area exposed to secondary outlet pressure and is quite sensitive to its fluctuations. The maintenance of a dynamic pump is easy as compared to the positive displacement pump. Here CSI can help.

3 in a buffer wet transfer or by b placing the gel-membrane sandwich between absorbent paper soaked in transfer buffer semi-dry. And each cylinder has a piston. The piston pump is a single or double-acting pump.

Minimum wear as compared to others. Electroelution can be achieved either by a complete immersion of a gel-membrane sandwich Fig. These elements are either made of circular metal discs or flexible materials including rubber plastic or leather.

This reciprocating bilge pump uses one cylinder and a piston to increase the pressure of the water. III Single Stage Pump. They need a short space for installation.

A cell can either perfectly repair itself and continue unharmed it can die in the process of reproduction or it can repair itself imperfectly causing it. These types of structures reduce both materials and construction costs.

Diaphragm Pump Its Functioning Advantages Disadvantages

The Solids Handling Workhorses Of The Sandpiper Pump Line For More Info Visit Http Www Idexindia In Sandpiper Pump Heavy Duty Pumps Valve Gpm Sandpiper

What Is A Diaphragm Pump How Does A Diaphragm Pump Work

The Main Role Of The Pressure Reducing Valve Hydraulic Systems Valve Mechanical Design

3 Big Advantages Of Using Diaphragm Agricultural Pumps

Safety Relief Valve A Pressure Relieving Device Safety Valve Relief Valve Hydraulic Systems

What Are Piston Pumps Parts Types Working Applications Diaphragm Pump Pistons Gear Pump

0 comments

Post a Comment